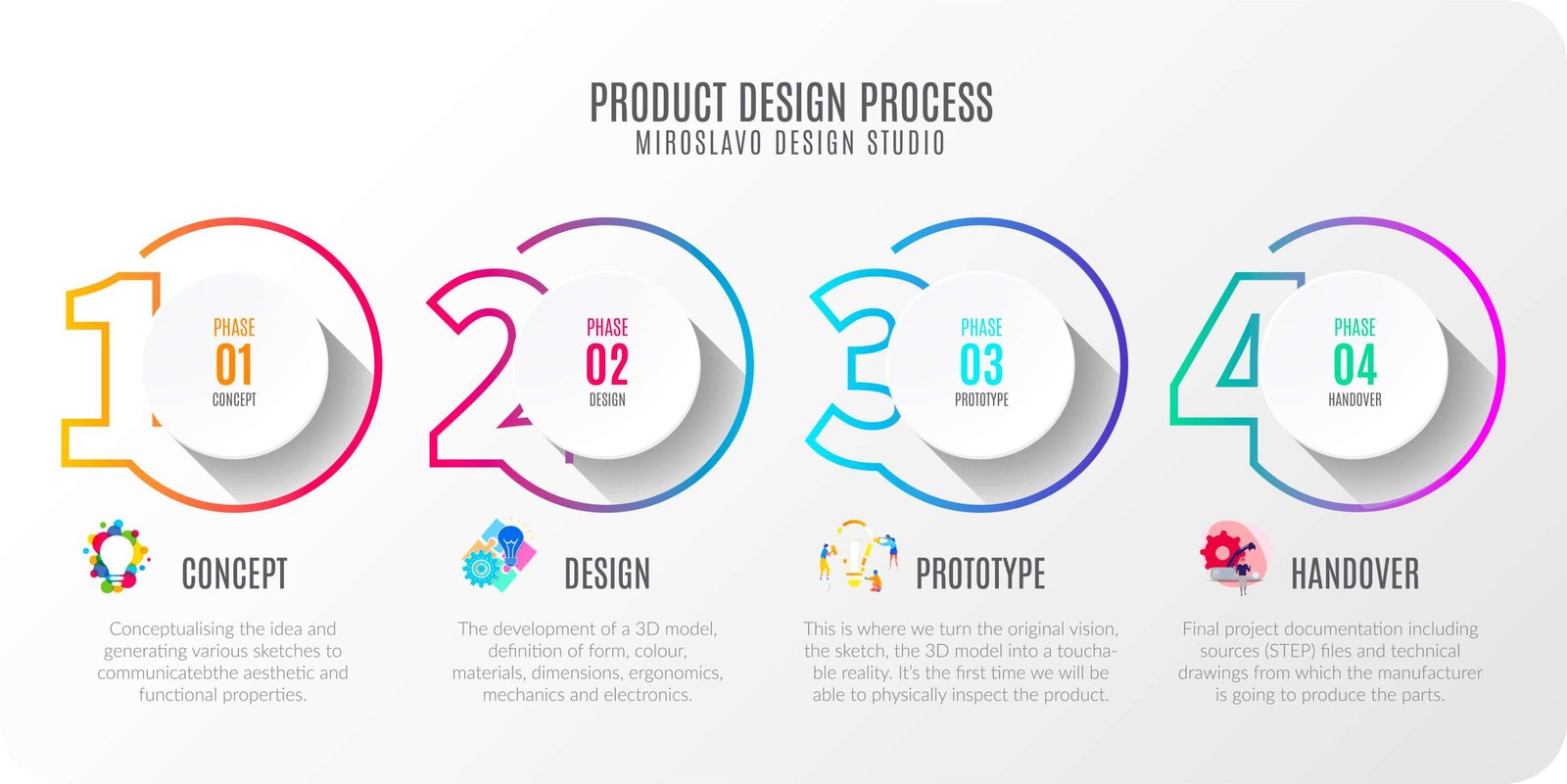

In this article, I would like to show you the four phases that are undertaken in a product design project meant for mass production. Designing and developing a new product or packaging is always a journey, and having a clear idea of what to expect from it is important for anyone who wants to bring their idea to market. At our industrial design studio, we divide such projects into 4 key stages when working with our clients. Each stage generates its own result and has its own little process.

1. Conceptualisation phase

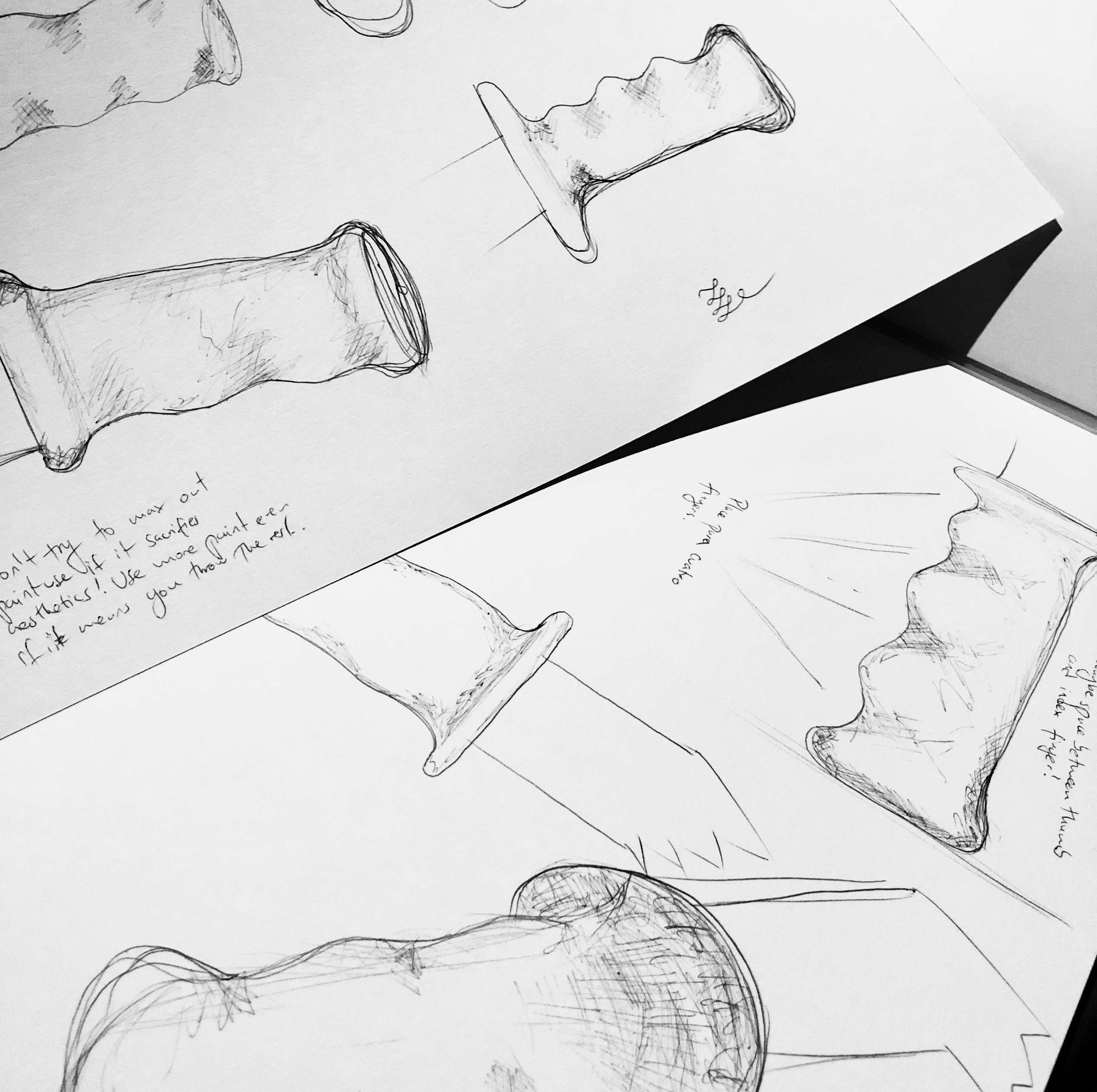

This is the first key part of the process. When a client approaches us with an idea, usually, they have some form of background research they conducted, already know the market, their potential competitors, and their vision about the product roughly defined.

In this stage, we get to know everything about their idea and expand on the knowledge gathered. We then use that information to create a design concept, a sketch that will communicate what the product will do, how it will do it and what it’s going to look like. We might also define other details, like possible manufacturing methods or materials.

2. Design phase

In this phase, we build on the knowledge and drawings we generated in the previous stage and begin developing the concept using 3D modelling software. We will typically define the colour, form, materials, dimensions, and basically all the necessary visual and functional properties of the product in this phase. We will make a 3D model that will be the closest to the final product in terms of aesthetics and functionality. We will take into consideration assembly/disassembly, sustainability and potential end manufacturing process if required. In this phase, we develop a model that is ready to be built into a functional prototype. We then move on to the validation and prototyping phase.

3. Prototyping phase

Here is when we take a very important leap in turning an idea, a model and a dream into a physical and tangible invention. It’s a very exciting process. Seeing it go from the previous phases to something that stands, inspires and functions is amazing for all parties involved.

The prototype development has its own unique creative and problem-solving process. It consists of multiple iterations. We also use various prototyping technology involving 3D printing, CNC machining, vacuum casting or simple paper prototyping.

Overall, this phase gives us valuable feedback and validates the knowledge we generated in the previous stages. Sometimes, the prototype shows us new information that requires us to go back to the previous stages to make certain improvements or changes. Once we have a prototype that meets all requirements, we move into the handover phase. This is to give the manufacturers information on the design and technical details, based on which they will develop it into a mass-producible product.

4. Handover phase

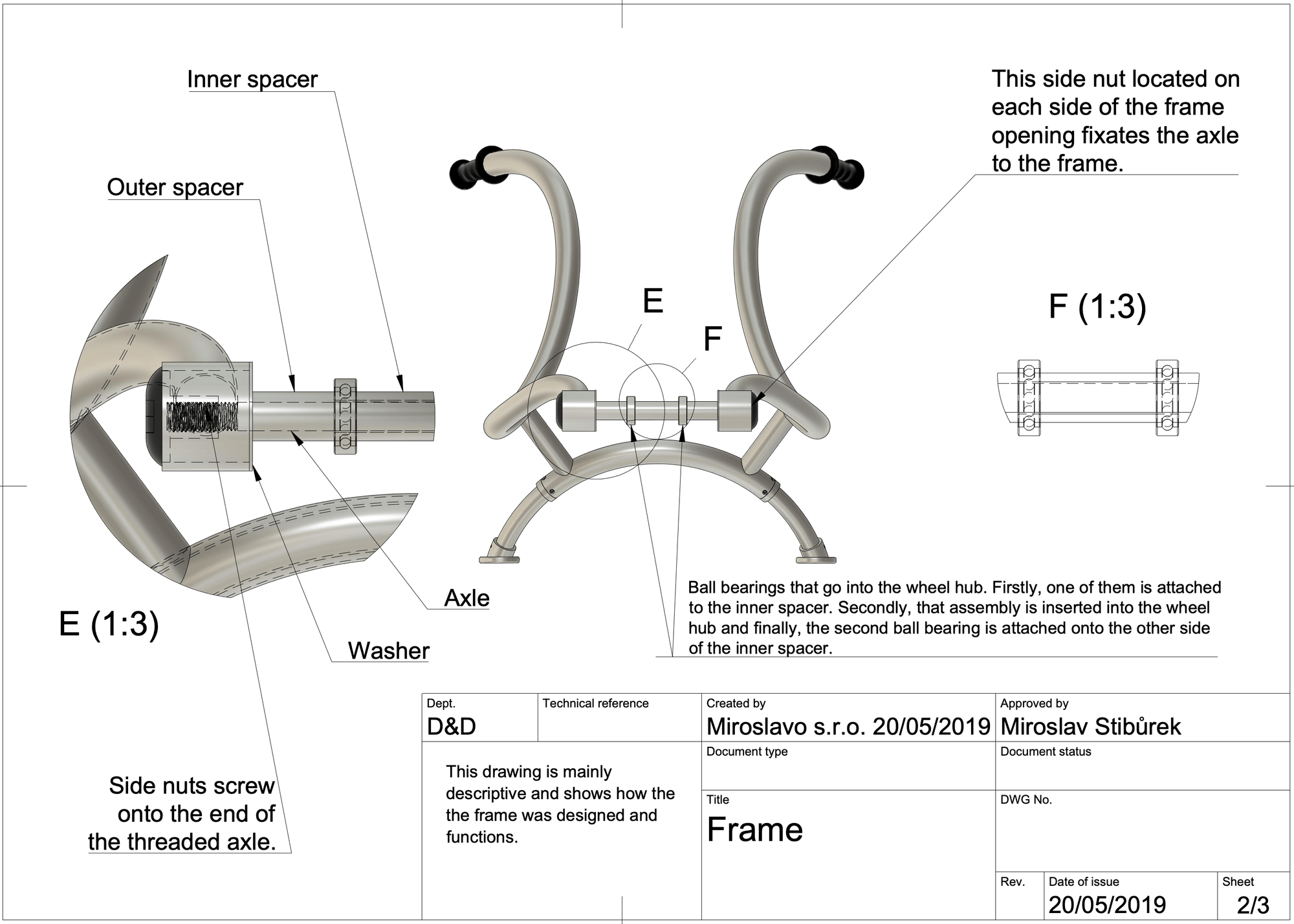

In the final stage of our product design, we generate project documentation including 2D drawings and source files of the final models that will enable the manufacturer to produce the parts and understand the assembly. Sometimes there will be feedback from the manufacturer about some aspects of the design, which might require making amendments.

Once this process is finished, we hand it over, and then it’s in the hands of the manufacturer to produce it according to our drawings and supply you with the parts or assembly.

This is, more or less, the process of developing the product’s design. Sometimes, the project requires the industrial designer‘s supervision over the manufacturing process or assistance in the post-manufacturing and marketing stage.

Are you looking to bring a new product idea to life or enhance an existing one? Look no further. At MIROSLAVO® DESIGN, we specialise in industrial design and innovation, and we’re here to help you bring your vision to fruition. Let’s discuss your project and see how we can turn your idea into a reality.